- +Manufacturing method

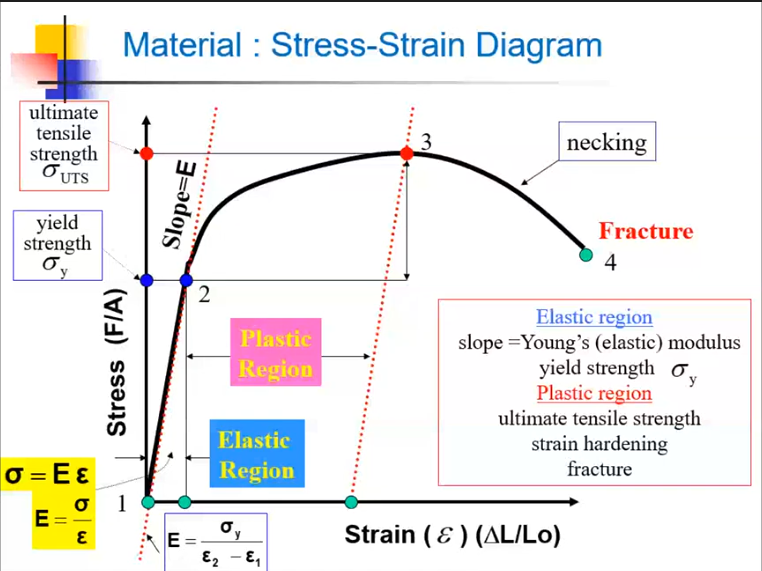

- and are constant regardless of the dimensions and load

- However, stress varies with strain

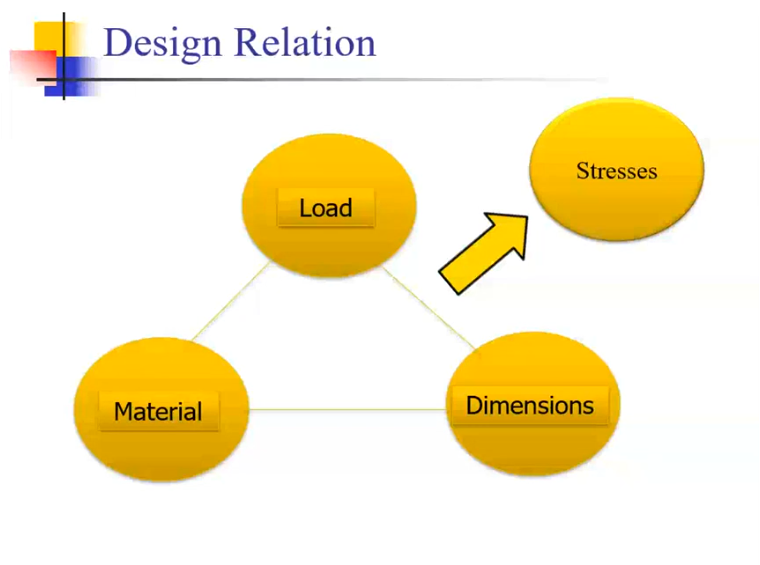

- For a given material, strength is a property of this material, but stress on a part made of this material depends on the dimensions and load applied on this part

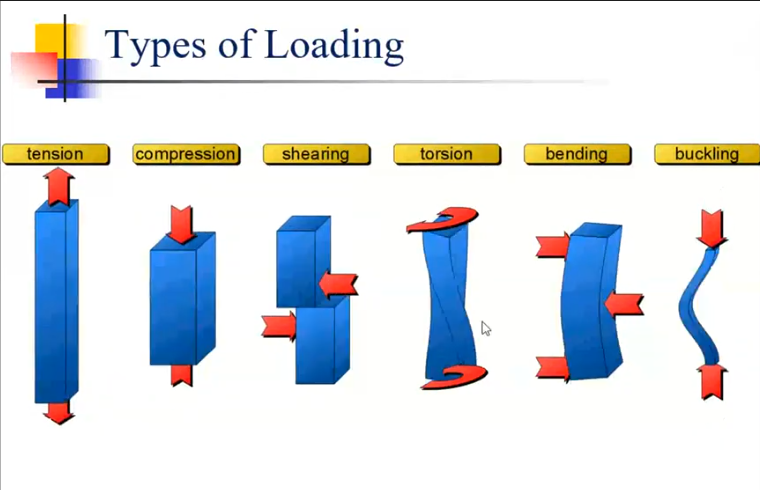

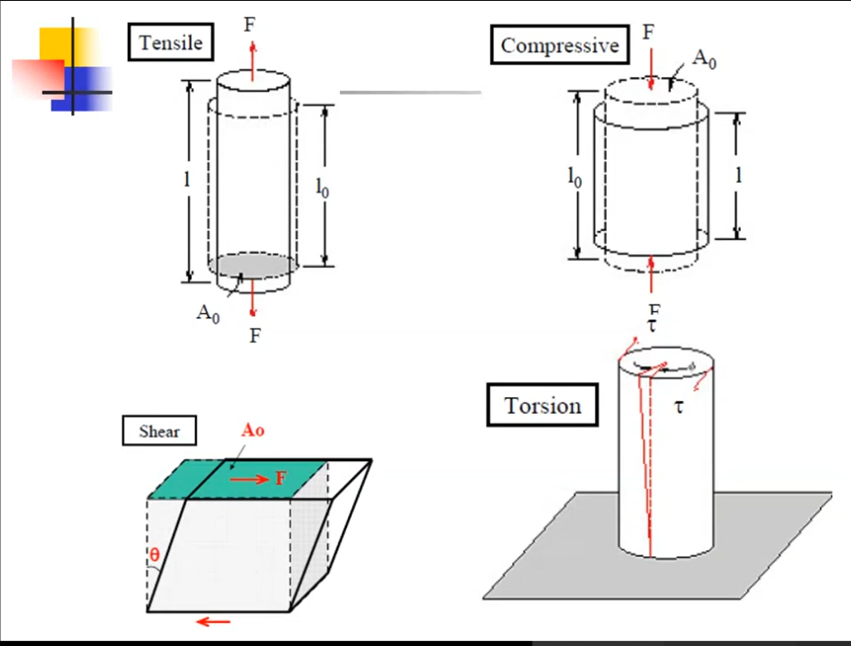

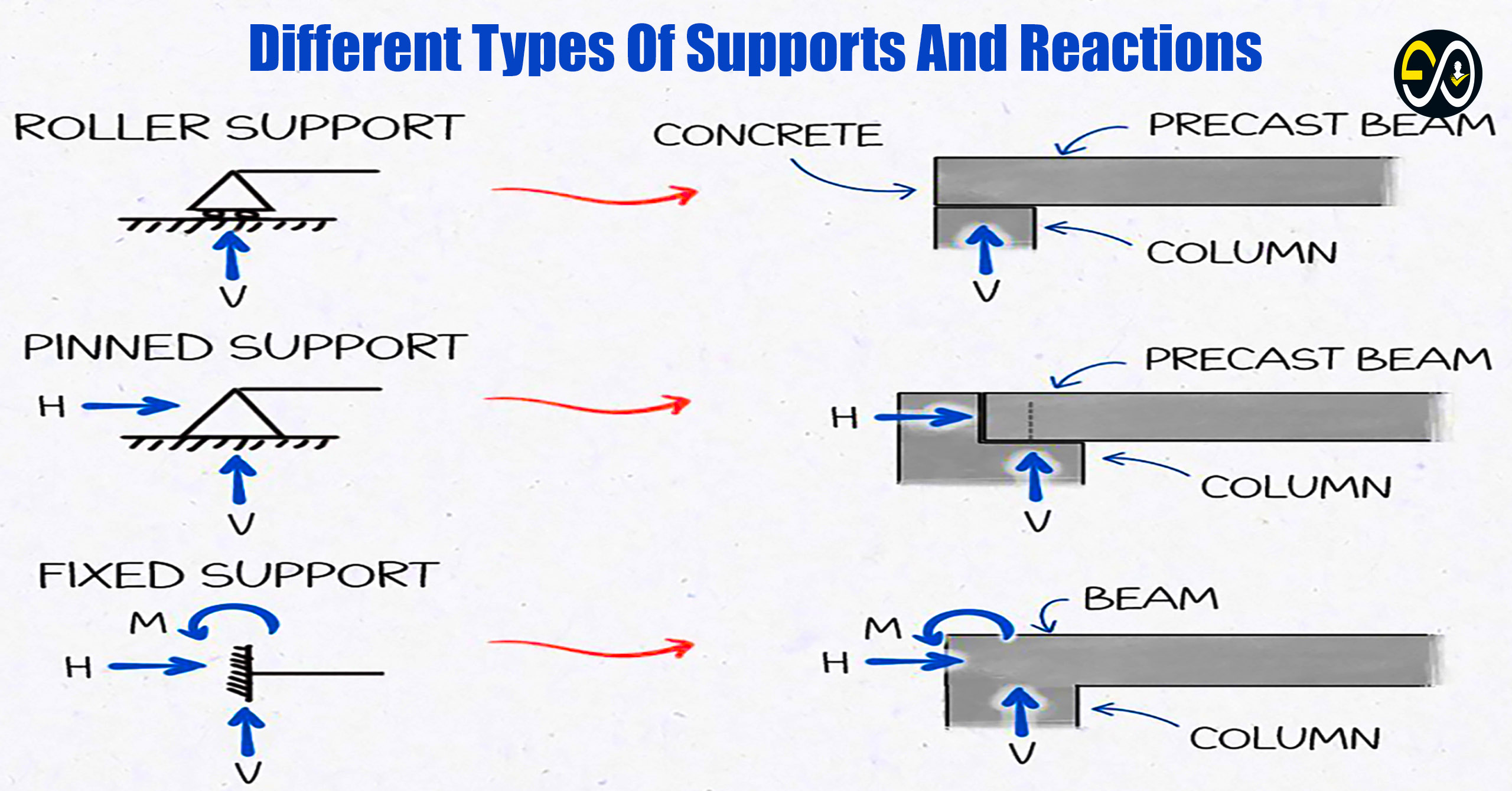

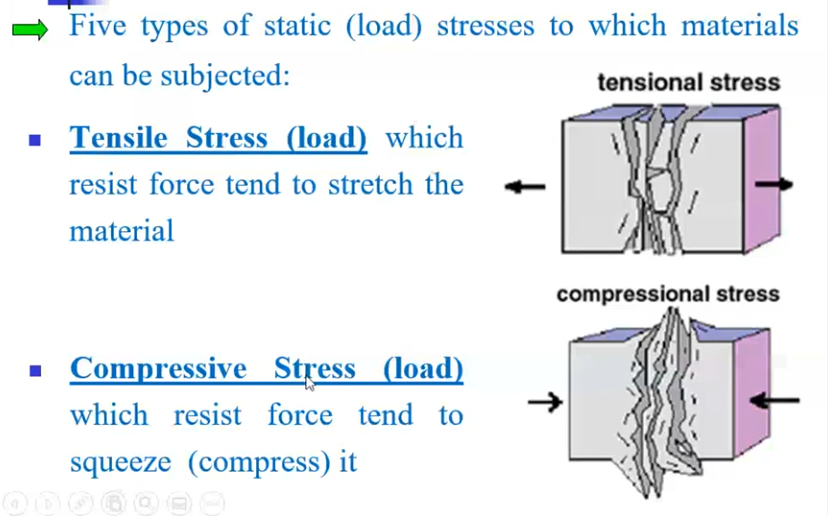

- Load perpendicular on cross-sectional area Tension or Compression

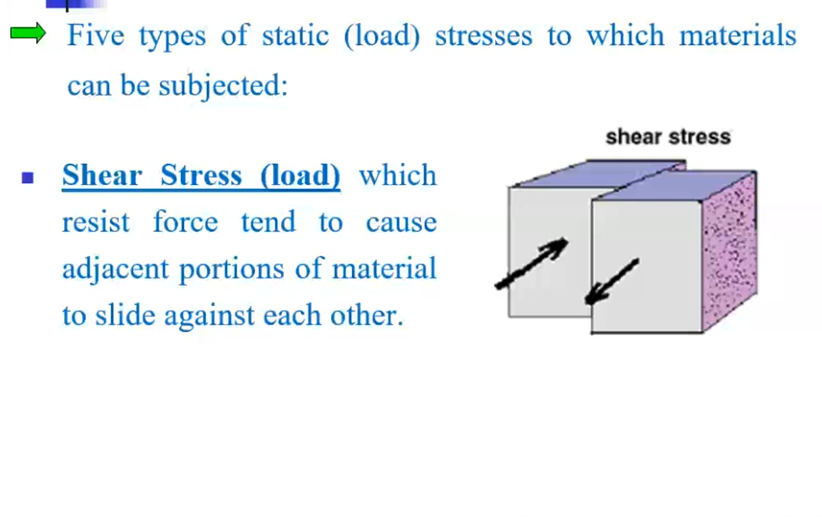

- Load parallel to cross-sectional area Shear or Bending

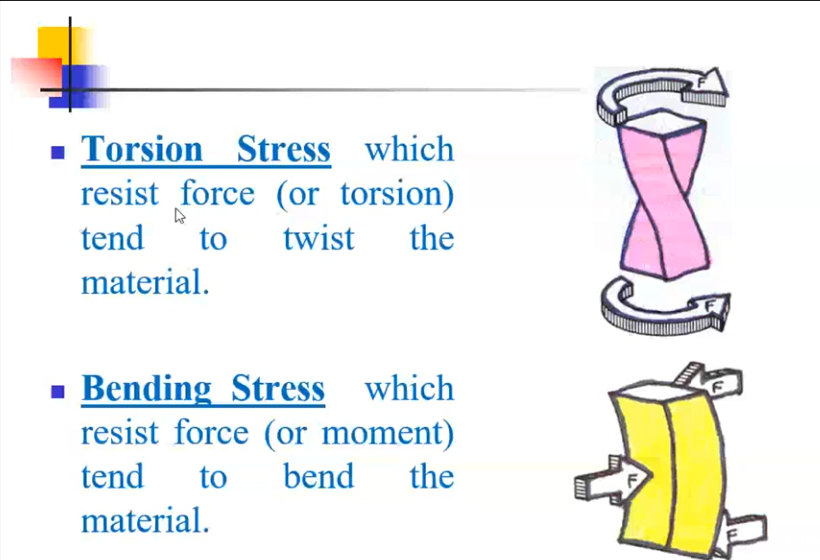

- Load twists/squeezes the part Torsion

Where are Force, Moment, Torsion, and Torque from this map?

- Stress (the internal resistance of the material) varies according to the applied load and dimensions

- Material Strength is the maximum Stress a material can sustain (before plastic deformation Yield Strength | before failure Ultimate Tensile Strength)

37:18 The choice of load to be applied on the material depends on the application (what you want to do with the material), which means designing for a certain Material Strength

- Design Before Yield Strength

- Extrusion After Yield Strength and Before Ultimate Tensile Strength

- Piercing & Blacking After Ultimate Tensile Strength

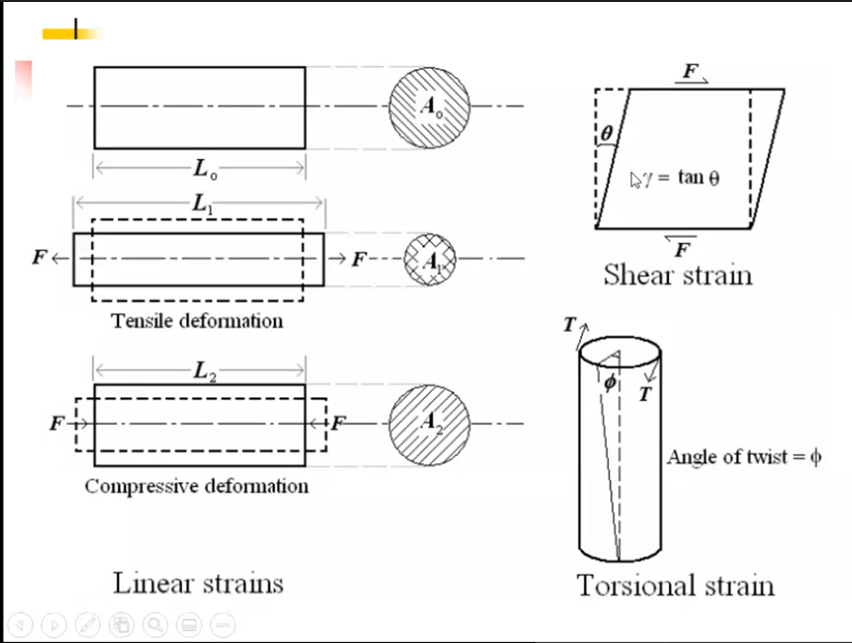

- The main strain is the one along the direction of the applied load (this is called Longitudinal Strain)

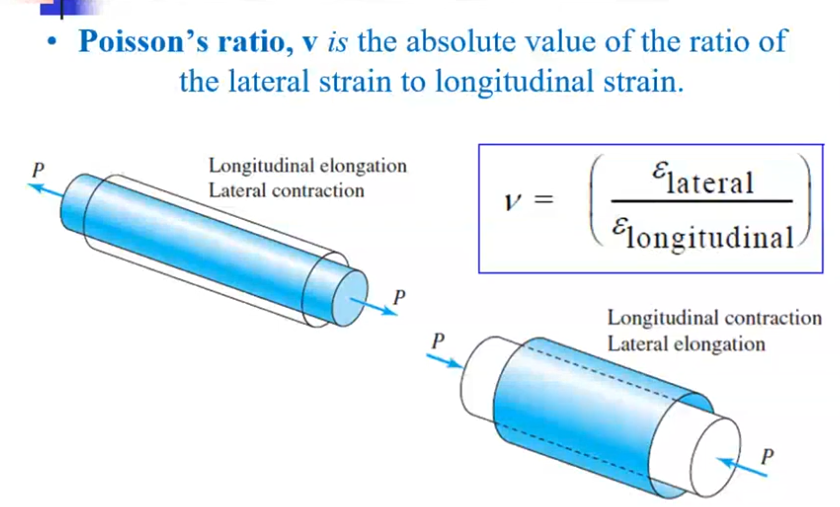

- The strain perpendicular to the direction of the applied load is called Lateral Strain

- Poisson’s Ratio recognizes that the ratio between the lateral and longitudinal strain is constant for a given material

- Stress is still a general concept of internal resistance to the applied load, regardless of the type of that loading (force, torsion, moment)